SOLUTIONS

Bioreactors – Automated Smart Composting Systems

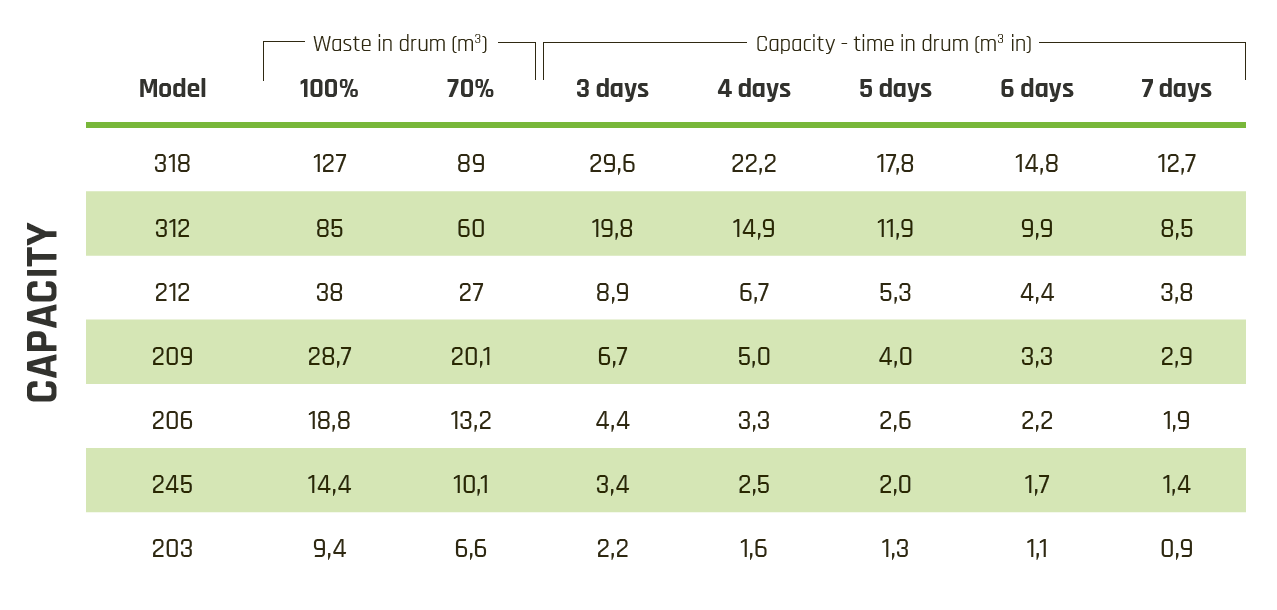

The Biocompost bioreactor is an in-vessel composting system that allows you to rapidly compost solid organic waste from restaurants, grocery stores, households, factories, processing plants, farms, municipalities and so forth. The Bioreactor rotating drum composting large volumes of solid waste in just 3 to 7 days and offers a complete “green” solution and competitieve Return on Investment.

THIS IS HOW IT WORKS

- The composting drum is filled with organic waste.

- The drum spins at 240 revolutions per day and, when oxygen is added, an accelerated composting process begins.

- The waste is naturally heated during composting, starting a hygenisation process that kills infectious agents and weeds.

- The end product is nutrient-rich fertiliser that can be used in your own business or sold.

- The process takes three to seven days, compared to months in traditional compost. Once the waste is in the drum - the process is odourless

ENGINNEERING AND DESIGN

ADDED VALUE

1. Pilot study

The general processes involved in composting are well documented. Carbon, nitrogen, moisture and nutrient content are among the many factors that play a role. In order to ensure successful composting, we need to study your specific conditions.

2. Laboratory analysis

By analysing your raw materials, we can develop a recipe that meets your specific needs – ensuring that composting achieves the best possible results. We can even perform financial and commercial calculations regarding the compostability of your materials.

3. Optimisation

We test and evaluate a range of alternatives to develop the optimal end product. This is a matter of adjusting and determining the recipes and mixtures that will then undergo full-scale processing.

4. Implementation

We take part in commissioning at your premises and satisfy ourselves that the desired results are being achieved. Further optimisation may be required at this point, as it is not possible to completely simulate the process in a full-size composting drum in a laboratory environment.

BENEFITS

Rotating bioreaktor

The bioreactor rotates at 10 times per hour. The size of the motor depends on the size of the vessel but ranges from 5 to 10 hp. Note that the ends of the BioReactor are fixed and only the cylinder rotates.

Solid organic waste

The precisely engineered reactor composting technology tightly controls the decomposition process of solid organic waste and reliably converts organic material into nutrient-rich humus. The resulting hygienized compost bears no resemblance to the waste from which it was converted.

Green solution

The Biocompost bioreactor is an in-vessel composting system that allows you to rapidly compost solid organic waste from restaurants, grocery stores, households, factories, processing plants, farms, municipalities and so forth. The Bioreactor rotating drum composting large volumes of solid waste in just 3 to 7 days and offers a complete “green” solution and competitieve Return on Investment.

BIOREACTORS

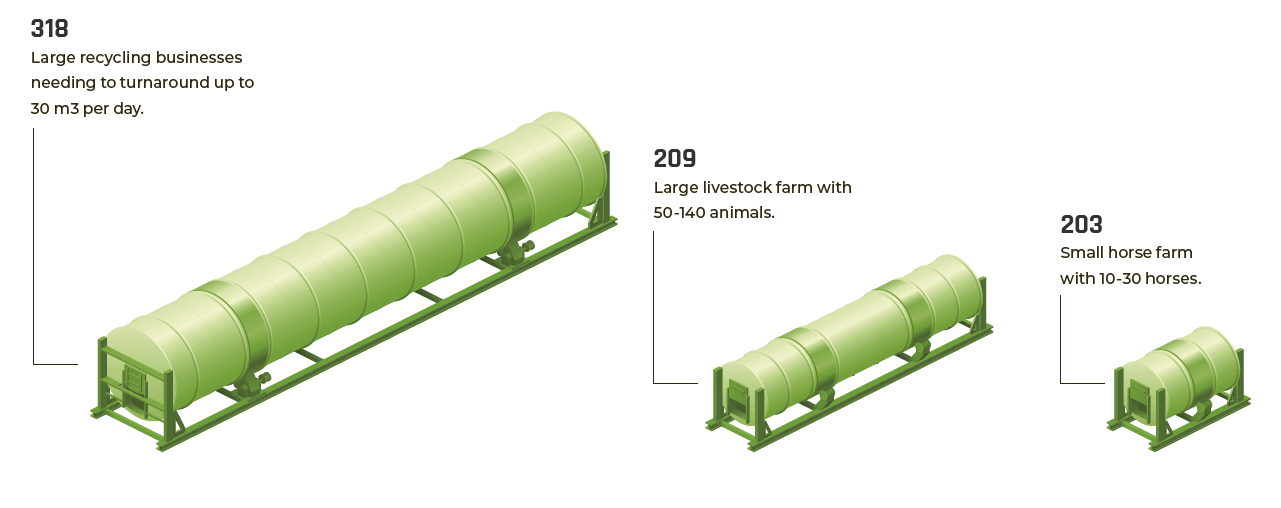

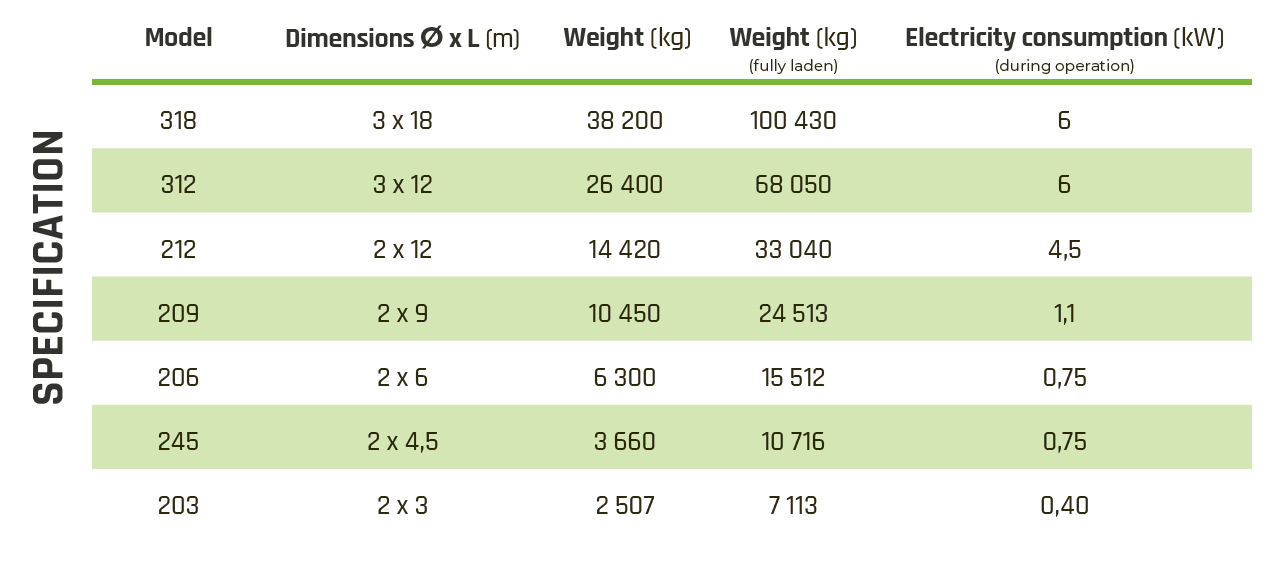

Which product suits your business?

Biocompost have seven different drum composters to choose from.

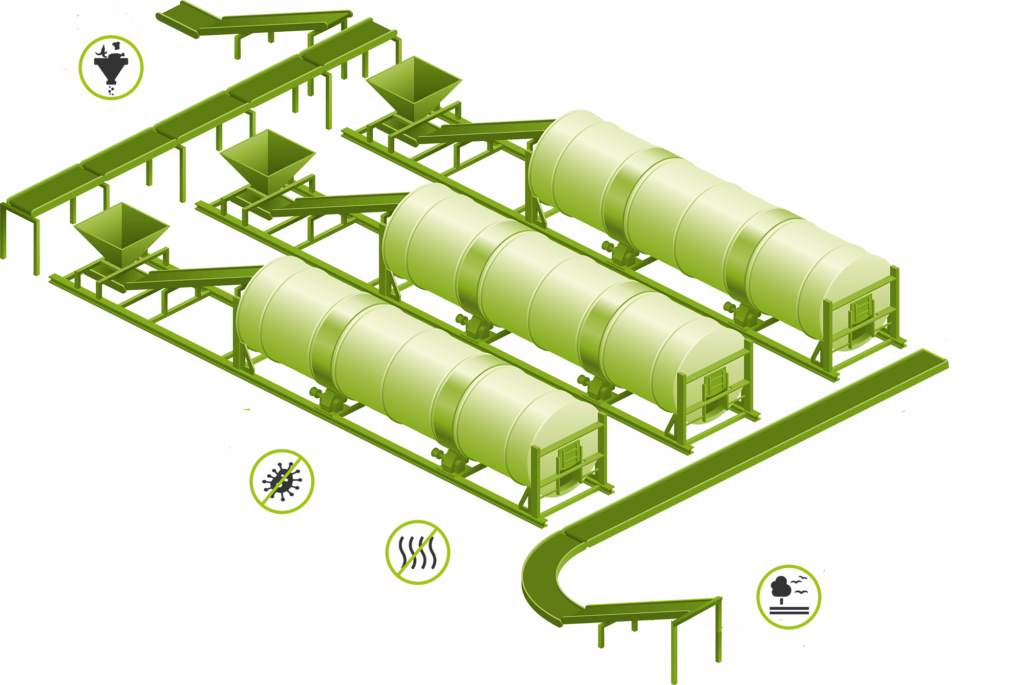

Accessories

- Mixers for blending

- Grinders for particle size reduction

- Infeed and outfeed screw conveyors

- Distribution conveyor with automatic spreader outfeed